Ukushisela kwe-TIG kwaqalwa eMelika (e-USA) ngo-1936, okwaziwa ngokuthi i-Argon arc welding. I-TIG ivumela amajoyinti ashiselwe asezingeni eliphezulu ukuthi akhiqizwe ngezisekelo zegesi ezingasebenzi kahle ezinemiphumela yokushisela ehlanzekile. Le ndlela yokushisela iyinqubo yokushisela ehloselwe zonke izinjongo maqondana nezinto ezisetshenzisiwe, ubukhulu bodonga, kanye nezikhundla zokushisela.

Izinzuzo zale ndlela yokushisela azikhiqizi ukuchitheka okuncane kanye nokungcola okuncane ngenkathi futhi kuqinisekisa ijoyinti elishisiwe lezinga eliphezulu uma lisetshenziswa kahle. Ukondla izinto ezisetshenziswayo zokushisela kanye nogesi akuxhumene, ngakho-ke lokhu kwenza i-TIG ifanelekele ukushisela izimpande kanye nokushisela okusendaweni.

Kodwa-ke, ukushisela kwe-TIG kudinga umshiseli oqeqeshwe kahle ukuze akusebenzise ngesandla esinekhono kanye nolwazi lokusetshenziswa okufanele kwe-voltage kanye ne-amperage. Lokho kuzosekela umphumela wokushisela we-TIG ohlanzekile nongcono kakhulu. Futhi ngicabanga ukuthi yilokhu okuyimbangela yokungasebenzi kahle kwe-TIG.

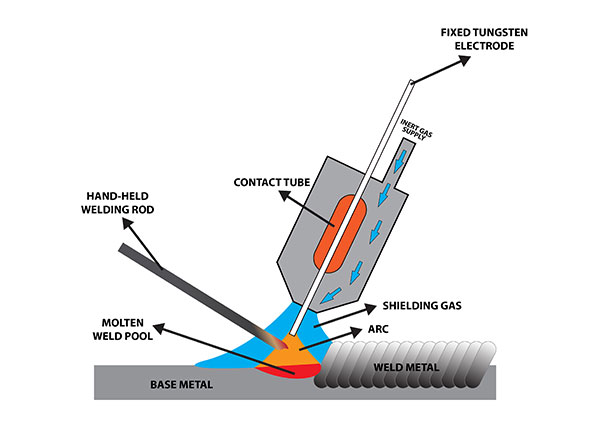

Njengoba ubona kuleso sithombe, ngemva kokucindezela inkinobho yethoshi, igesi iqala ukugeleza. Futhi lapho isihloko sethoshi sithinta ubuso bensimbi, kwenzeka i-short circuit. Ngenxa yobuningi bamandla aphezulu esicongweni sethoshi, insimbi iqala ukuhwamuka lapho ithinta khona bese i-arc ivutha, vele, imbozwe yigesi evikelayo.

UKUSETHA UKUCINDEZELWA KWEGESI/UKUGQIBELA

Izinga lokugeleza kwegesi lingama-l/min futhi lincike kusayizi wechibi lokushisela, ububanzi be-electrode, ububanzi be-nozzle yegesi, ibanga le-nozzle ebusweni bensimbi, ukuhamba komoya okuzungezile kanye nohlobo lwegesi evikelayo.

Umthetho olula uwukuthi amalitha ama-5 kuya kwayi-10 egesi yokuvikela kufanele engezwe ku-argon njengegesi yokuvikela kanye nobubanzi be-tungsten electrode esetshenziswa kakhulu, ngesilinganiso esingu-1 kuya ku-4 mm ngomzuzu.

ISIMO SESITOSHI

Njengaku-MIG Welding, indawo yethoshi, uma usebenzisa indlela ye-TIG Welding, nayo ibaluleke kakhulu. Indawo yethoshi kanye nenduku ye-electrode kuzothinta imiphumela ehlukene yokuwelda.

I-Electrode ngokwayo iyinto esetshenziswayo yokushisela esetshenziswa ngesikhathi sokushisela i-TIG. Izinto ezisetshenziswayo zokushisela zivame ukukhethwa ngendlela efanayo nohlobo lwensimbi. Kodwa-ke, ngenxa yezizathu zensimbi, kuyadingeka ukuthi izinto ezisetshenziswayo zokushisela ziphambuke ensimbini engumzali lapho kusetshenziswa izinto ezithile zokuhlanganisa.

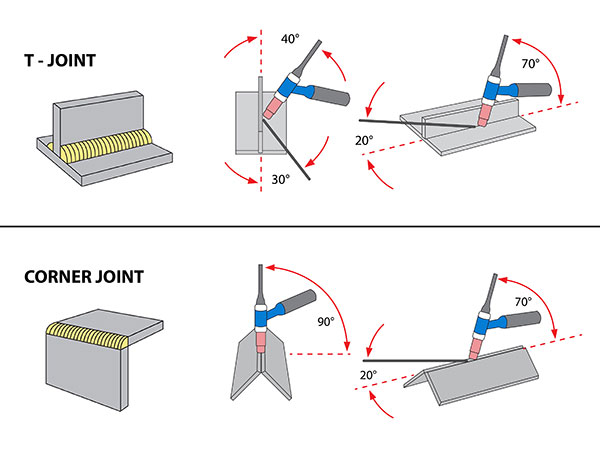

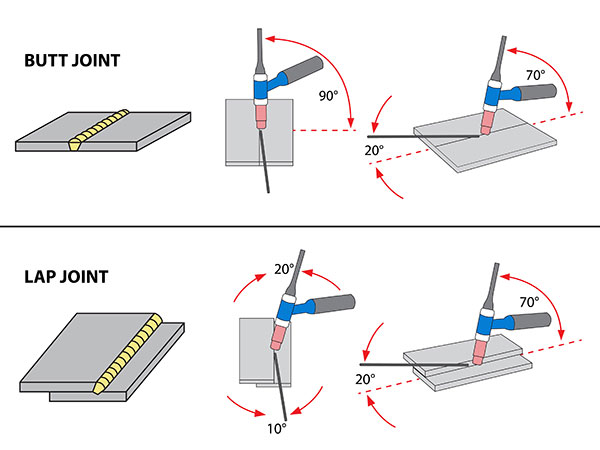

Buyela endaweni lapho ithoshi libekwe khona. Ungafaka izikhundla ezahlukene zethoshi le-TIG kanye nenduku ye-electrode ngenkathi uhlanganisa izinsimbi ezahlukene. Ngakho-ke indawo yethoshi incike ohlotsheni lwezinsimbi. Ngisho ukuthi kunezinsimbi ezine eziyisisekelo ezifana nalezi:

I-T- Joint

I-Corner Joint

I-Butt Joint

I-Lap Joint

Ungasebenzisa ezinye zalezi zikhundla zethoshi emisebenzini ofuna ukuyiqeda. Futhi uma usujwayelene nezikhundla zethoshi zokuwelda ezihlanganisiwe zensimbi, ungafunda ngemingcele yokuwelda.

AMAPHARAMETHI OKUSHINTSHA

Uma ukhetha amapharamitha okushisela, kufanele kuqashelwe ukuthi ugesi kuphela osetshenziswa emshinini wokushisela. I-voltage inqunywa ubude be-arc, obugcinwa yi-welder.

Ngakho-ke, ubude obukhulu be-arc budinga i-voltage ephezulu ye-arc. I-welding current engama-45 amperage nge-mm ngayinye yobukhulu bensimbi isetshenziswa njengenani lokubhekisela le-current eyanele ukuze insimbi ye-welding ithole ukungena okugcwele.

KUTHUNYELWE NGU-WENZHOU TIANYU ELECTRONIC CO., LTD.

Isikhathi sokuthunyelwe: Juni-12-2023