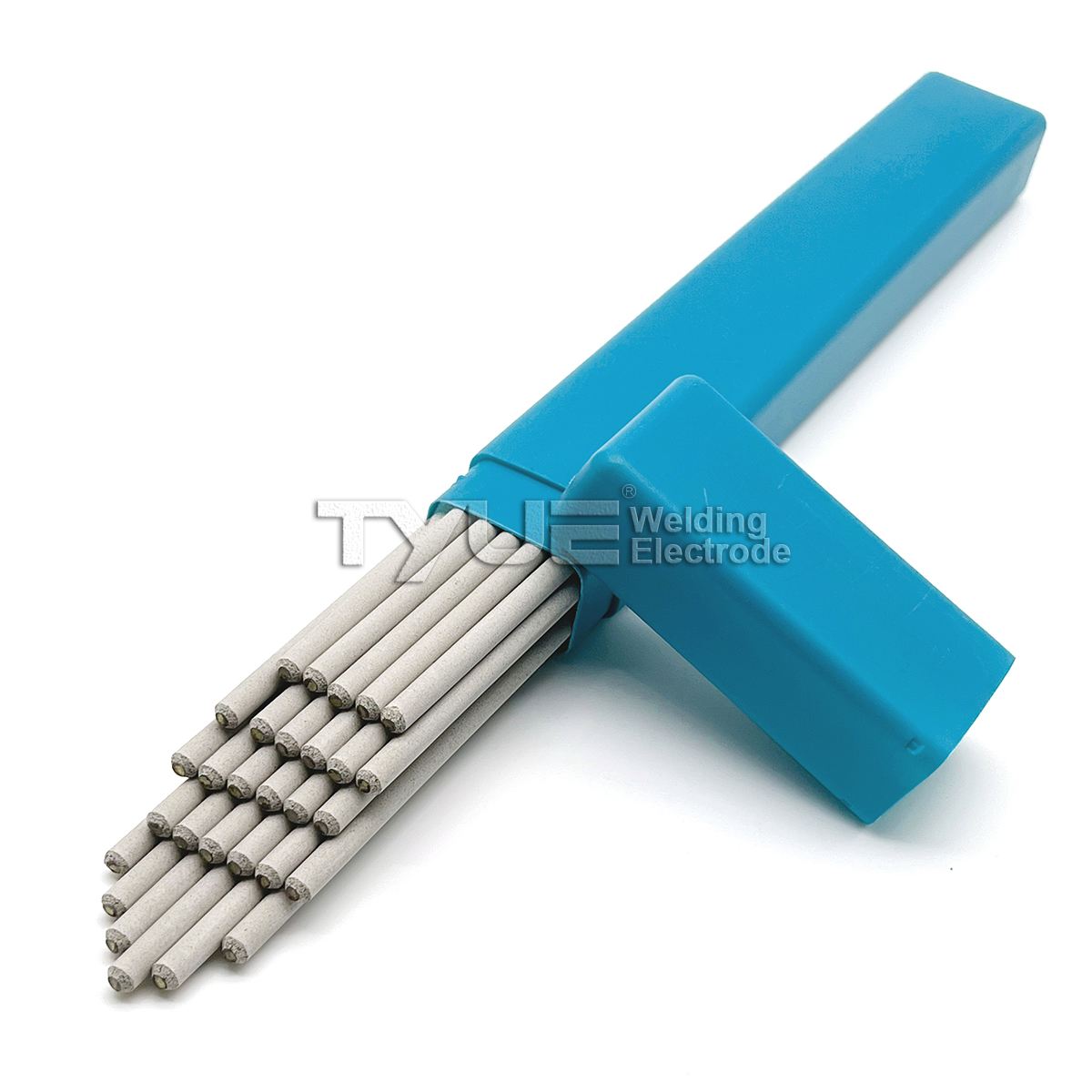

I-Electrode Yokushisela Yensimbi Ephansi Ye-Alloy

J707RH

I-GB/T E7015-G

I-AWS E10015-G

Incazelo: I-J707RH iyi-electrode ye-hydrogen enamandla kakhulu futhi ephansi kakhulu enombozo we-sodium we-hydrogen ephansi. Sebenzisa i-DCEP (i-electrode yamanje eqondile) futhi ingashintshwa kuzo zonke izikhundla. Ukusebenza kwenqubo yokushintshwa kuhle. Ukugoba okubandayo, ukumelana nokuqhekeka kanye nokumelana nokuqhuma kwamalunga ashintshwayo kuhle. Insimbi efakiwe inokuqina okuhle kanye nokuqina.

Ukusetshenziswa: Isetshenziselwa ukushisela izakhiwo ze-shell, futhi ifanelekela nokushisela izakhiwo ezibalulekile zensimbi enamandla aphezulu ye-Rp0.2≥590MPa.

Ukwakheka kwamakhemikhali kwensimbi eshidiwe (%):

| C | Mn | Cr | Si | Ni | Mo | S | P | S + P |

| ≤0.10 | 1.20 ~ 1.60 | 0.08 ~ 0.20 | 0.30 ~ 0.60 | 1.40 ~ 2.00 | 0.25 ~ 0.50 | ≤0.020 | ≤0.020 | ≤0.035 |

Izakhiwo zemishini zensimbi yokushisela:

| Into yokuhlola | Amandla okudonsa I-Mpa | Amandla okukhiqiza I-Mpa | Ukwelulwa % | Inani lomthelela (J) -50℃ |

| Kuqinisekisiwe | ≥690 | ≥590 | ≥15 | ≥34 |

Okuqukethwe kwe-hydrogen okusabalala kwensimbi egciniwe: ≤4.1mL/100g (indlela ye-mercury noma i-gas chromatography)

Ukuhlolwa kwe-X-ray: Ibanga lokuqala

I-current enconyiwe:

| (mm) Ububanzi benduku | 4.0 | 5.0 |

| (A) Ukushisela Kwamanje | 160 ~ 180 | 180 ~ 220 |

Isaziso:

1. I-electrode kumele ibhakwe amahora ama-2 ku-400℃ ngaphambi kokusebenza kokushisela;

2. Kubalulekile ukuhlanza izikali zikawoyela, amanzi kanye nokungcola okugqwalile ezingxenyeni zokushisela ngaphambi kokushisela;

3. Sebenzisa umsebenzi omfushane we-arc lapho ushisela. Indlela encane yokushisela ifanelekile.