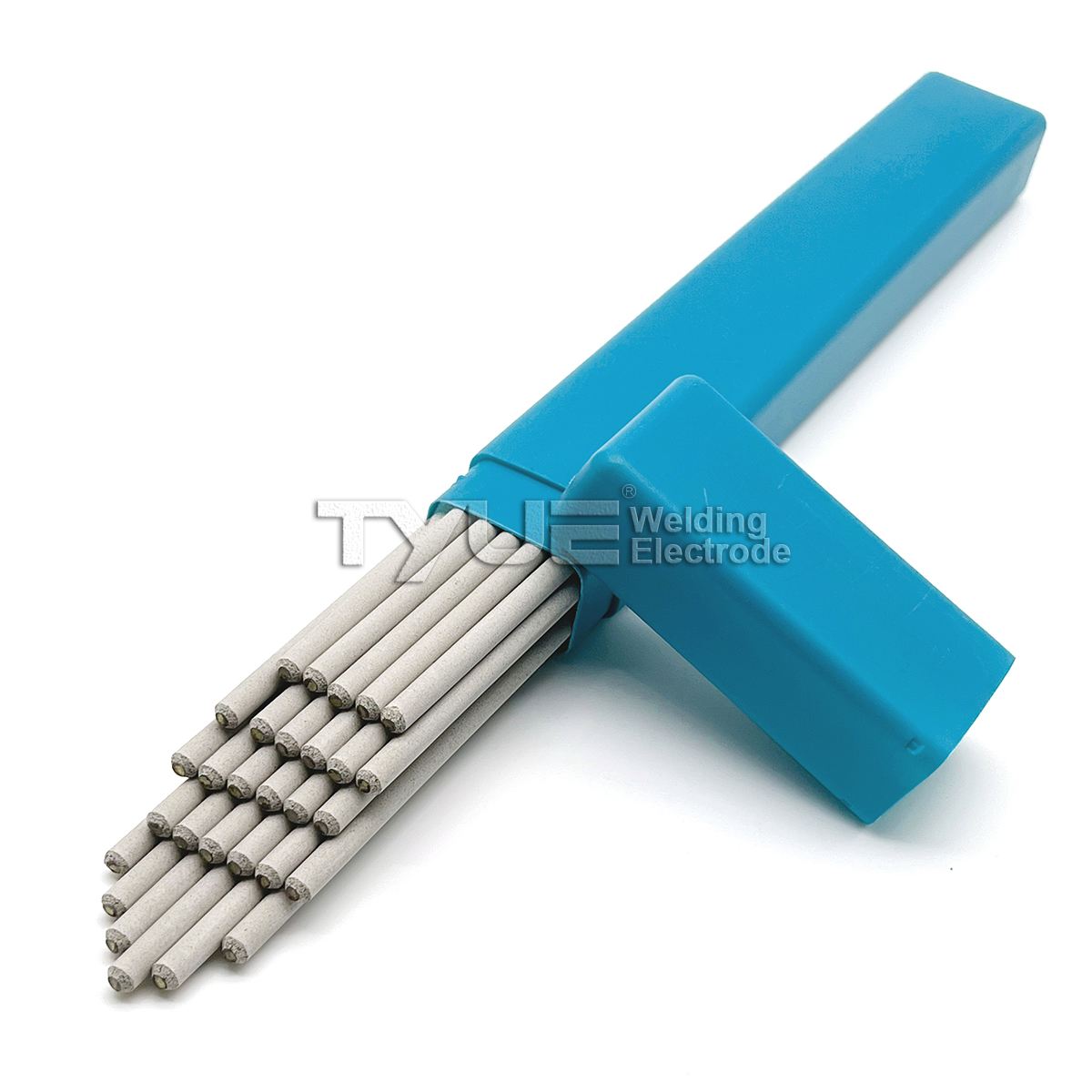

I-Electrode Yokushisela Yensimbi Ephansi Ye-Alloy

J555G

I-GB/T E5510-G

I-AWS A5.5 E8010-G

Incazelo: I-J555G iyi-electrode ephansi evundlile ene-cellulose ephezulu ene-sodium. Sebenzisa i-DCEP (i-electrode yamanje eqondile). Ifaneleka ekushiseni okuqondile okuvundlile okubheke phansi komthungo ojikelezayo endaweni yepayipi. Ingashiselwa ohlangothini olulodwa futhi yakheke nhlangothi zombili, futhi isivinini sokushisela siyashesha.

Isicelo: Isetshenziselwa ukushisela i-girth yamapayipi ahlukahlukene ensimbi aphansi.

Ukwakheka kwamakhemikhali kwensimbi eshidiwe (%):

| C | Mn | Si | S | P |

| ≤0.20 | ≥1.00 | ≤0.50 | ≤0.035 | ≤0.035 |

熔敷金属力学性能 Izakhiwo zemishini ye-weld metal:

| Into yokuhlola | Amandla okudonsa I-Mpa | Amandla okukhiqiza I-Mpa | Ukwelulwa % | Inani lomthelela (J) -30℃ |

| Kuqinisekisiwe | ≥540 | ≥440 | ≥17 | ≥27 |

Ukuhlolwa kwe-X-ray: Ibanga lesi-II

I-current enconyiwe:

| (mm) Ububanzi benduku | 2.5 | 3.2 | 4.0 | 5.0 |

| (A) Ukushisela Kwamanje | 40 ~ 70 | 70 ~ 110 | 110 ~ 160 | 160 ~ 190 |

Isaziso:

1. Khulula induku yokushisela ngaphambi kokusebenzisa, bese uyisebenzisa ngangokunokwenzeka ngemva kokuyivula;

2. Ngokuvamile, asikho isidingo sokuyomisa futhi ngaphambi kokuyishisela, futhi ingomiswa ku-70~90°C ihora eli-1 uma imanzi.

I-Wenzhou Tianyu Electronic Co., Ltd. yasungulwa ngo-2000. Besilokhu sihilelekile ekukhiqizenii-electrode yokushiselas, izinduku zokushisela, kanye nezinto ezisetshenziswayo zokushisela iminyaka engaphezu kwengu-20.

Imikhiqizo yethu eyinhloko ifaka insimbi engagqwalii-electrode yokushiselas, ama-electrode okushisela insimbi yekhabhoni,ama-electrode okushisela i-alloy ephansi, ama-electrode okushisela okungaphezulu, ama-electrode okushisela e-nickel kanye ne-cobalt alloy, izintambo zokushisela zensimbi emincane kanye ne-low alloy, izintambo zokushisela zensimbi engagqwali, izintambo ezivikelwe nge-gas-shielded flux cored, izintambo zokushisela ze-aluminium, ukushisela kwe-arc okungaphansi komhlaba. izintambo, izintambo zokushisela ze-nickel kanye ne-cobalt alloy, izintambo zokushisela zethusi, izintambo zokushisela ze-TIG kanye ne-MIG, ama-electrode e-tungsten, ama-electrode okugoqa i-carbon, nezinye izesekeli zokushisela kanye nezinto ezisetshenziswayo.