IZICELO:

Ukushisela kwezinsimbi ezingu-9% Cr-1% Mo kanye no-9% Cr – 2% Mo steels ezisetshenziselwa amandla kagesi nomkhumbi womfutho ophezulu.

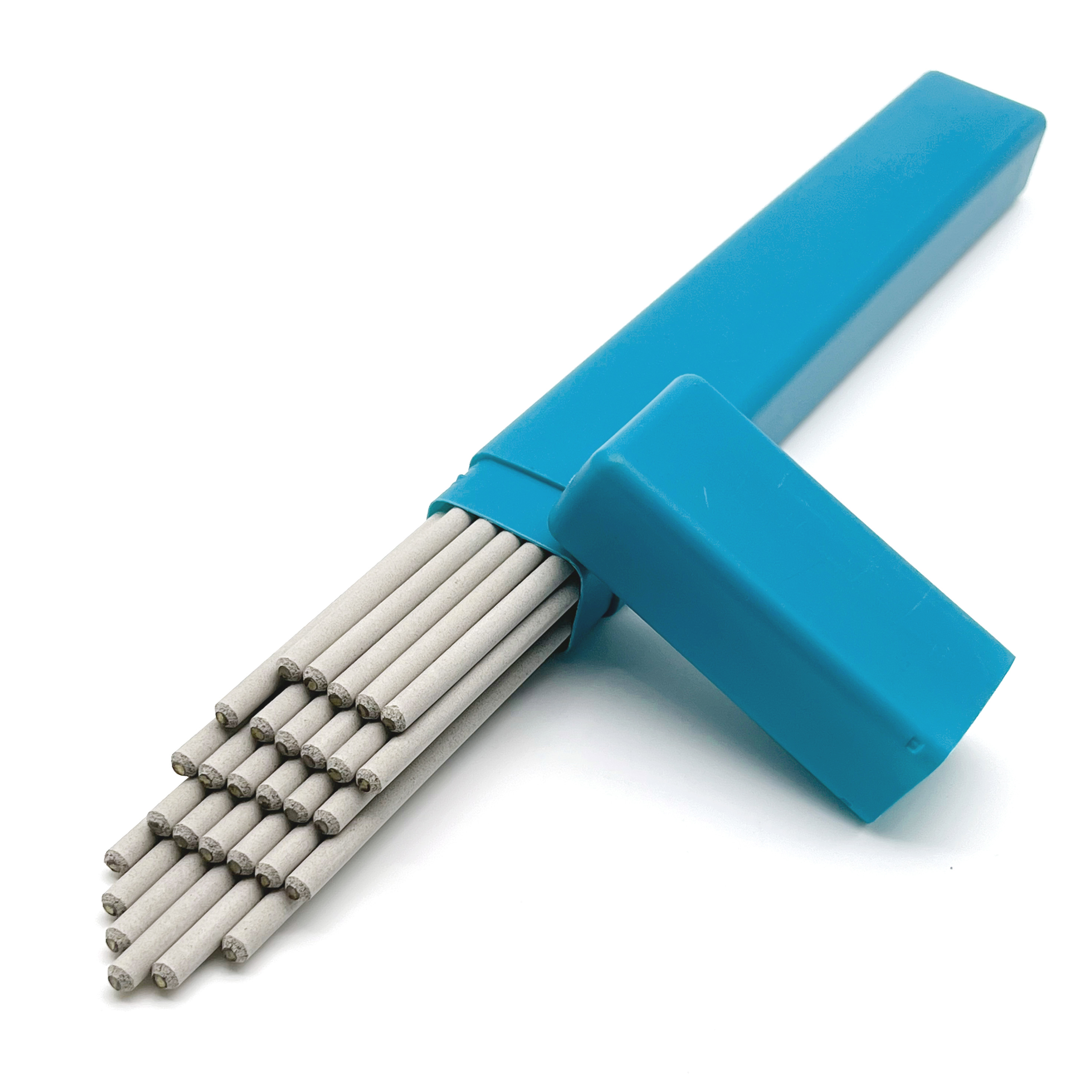

INCAZELO:

I-PA-8016-B8 iyi-electrode ephansi ye-hydrogen insimbi yayo yokushisela iqukethe u-9% Cr-1% Mo.Idizayinelwe izinga lokushisa eliphezulu lensimbi nezinsimbi zezinsiza ezishisayo ze-hydrogen, ikakhulukazi embonini ye-petrochemical.I-electrode ingavunyelwa ngenxa yamandla ayo aphezulu, ukuqina okuhle nokumelana nokushisa okukhulu.

AMAZWI OKUSETSHENZISWA:

1. Yomisa ama-electrode ku-350-400 ° C cishe ihora elilodwa ngaphambi kokusetshenziswa futhi ugcine ama-electrode ku-100-150 ° C ngemva kokuwomisa ngokunaka ukuze ugweme umswakama.

2. Yamukela indlela yesinyathelo esibuyela emuva noma ushaye i-arc epuletini lensimbi elincane elilungiselelwe le njongo ethile ukuvimbela ama-blowholes ku-arc ukuqala.

3. Gcina i-arc ibe mfushane ngangokunokwenzeka.

4. Shisisa kuqala ku-100-150°C.Izinga lokushisa elizosetshenziswa liyahlukahluka ngokuya ngobukhulu bepuleti kanye nohlobo lwensimbi ezoshiselwa.

5. Qaphela ukuthi ungadluli okokufaka okushisa okufanele ngoba okokufaka ukushisa okudlulele kubangela ukuwohloka kwamanani omthelela namandla esivuno sensimbi yokushisela.

IV.UKWAKHIWA KWEKHEMIKALI OKUJWAYELEKILE KWE-WELD METAL (%):

| C | Si | Mn | Cr | Mo |

| 0.06 | 0.42 | 0.68 | 9.38 | 1.05 |

V. IZIMPAHLA ZOMCHHANICAL EZIJWAYELEKILE YE-WELD METAL:

| Amandla Okuqina N/mm2(Ksi) | Iphoyinti Lokukhipha N/mm2 (Ksi) | Elongation % | I-PWHT |

| 705 (102) | 560 (81) | 24 | 740°C x 1 ihora |

VI.IZIKHUNDLA ZOKUSHISA: ZONKE IZIKHUNGO

VII.USIZI KANYE NOBANGA LWAMANJE OKUNCONYISWA (AC/DC+):

| Ububanzi (mm) | 2.5 | 3.2 | 4.0 | 5.0 | |

| Ubude (mm) | 350 | 350 | 400 | 400 | |

| I-Ampere | Isicaba | 55-85 | 90 - 130 | 130 - 180 | 180 - 240 |

| V & OH | 50 - 80 | 80 - 115 | 110 - 170 | 150 - 200 |