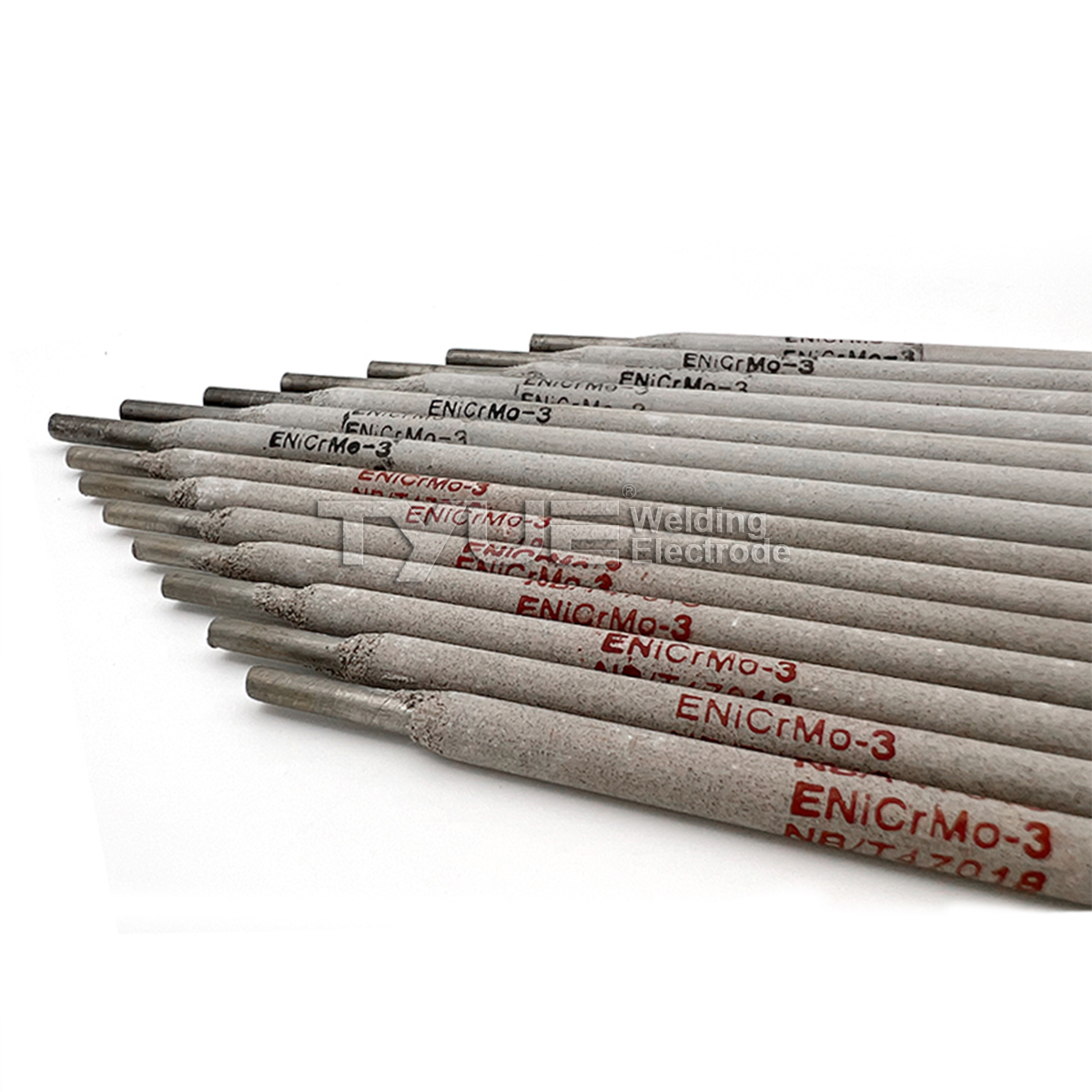

I-Nickel ne-Nickel AlloyUkushiselaI-Electrode

I-Ni327-3

I-GB/T ENi6625

Incazelo: I-Ni327 -3 i-electrode esekwe ku-nickel ene-low-hydrogen sodium coating.Sebenzisa i-DCEP (i-electrode yamanje eqondilepositive).Insimbi efakiwe inopulasitiki oncomekayo, ukuqina kanye nokumelana nokuqhekeka, futhi inamandla aphezulu kanye nokumelana nokugqwala okuqinile ekamelweni lokushisa kanye nokushisa okuphezulu.

Isicelo: Isetshenziselwa ukushisela ama-alloys e-nickel-chromium-molybdenum, ikakhulukazi ukushisela nokuvela kwe-UNS N06625 alloys nezinye izinhlobo zensimbi kanye nezinsimbi eziyinhlanganisela ye-nickel-chromium-molybdenum, futhi ingasetshenziselwa ukushisela i-Ni9% yensimbi ngaphansi. izimo zokushisa eziphansi.

Ukwakheka kwamakhemikhali ensimbi ye-weld(%):

| C | Mn | Si | Cr | Ni | Mo |

| ≤0.10 | ≤2.0 | ≤0.8 | 20.0 ~ 23.0 | ≥55.0 | 8.0 ~ 10.0 |

| Fe | Cu | Nb + Ta | S | P | Okunye |

| ≤7.0 | ≤0.5 | 3.0 ~ 4.2 | ≤0.015 | ≤0.020 | ≤0.5 |

Izici zemishini ye-weld metal:

| Into yokuhlola | Amandla aqinile Mpa | Amandla esivuno Mpa | Ukwelula % |

| Kuqinisekisiwe | ≥760 | ≥420 | ≥27 |

Okwamanje okunconyiwe:

| Ububanzi benduku (mm) | 2.5 | 3.2 | 4.0 |

| Ukushiselaokwamanje (A) | 50 ~ 70 | 80 ~ 100 | 110 ~ 150 |

Isaziso:

- I-electrode kufanele ibhakwe ihora elingu-1 endaweni engaba ngu-300 ℃ ngaphambi kokusebenza kokushisela.Zama ukusebenzisa i-arc emfushane ukushisela;

- Kubalulekile ukuhlanza okugqwalile, uwoyela, amanzi, nokungcola ezingxenyeni zokushisela ngaphambi kokushisela.

3. Zama ukusebenzisa amandla kalayini omncane lapho welding, multi-layer kanye multi-pass welding.