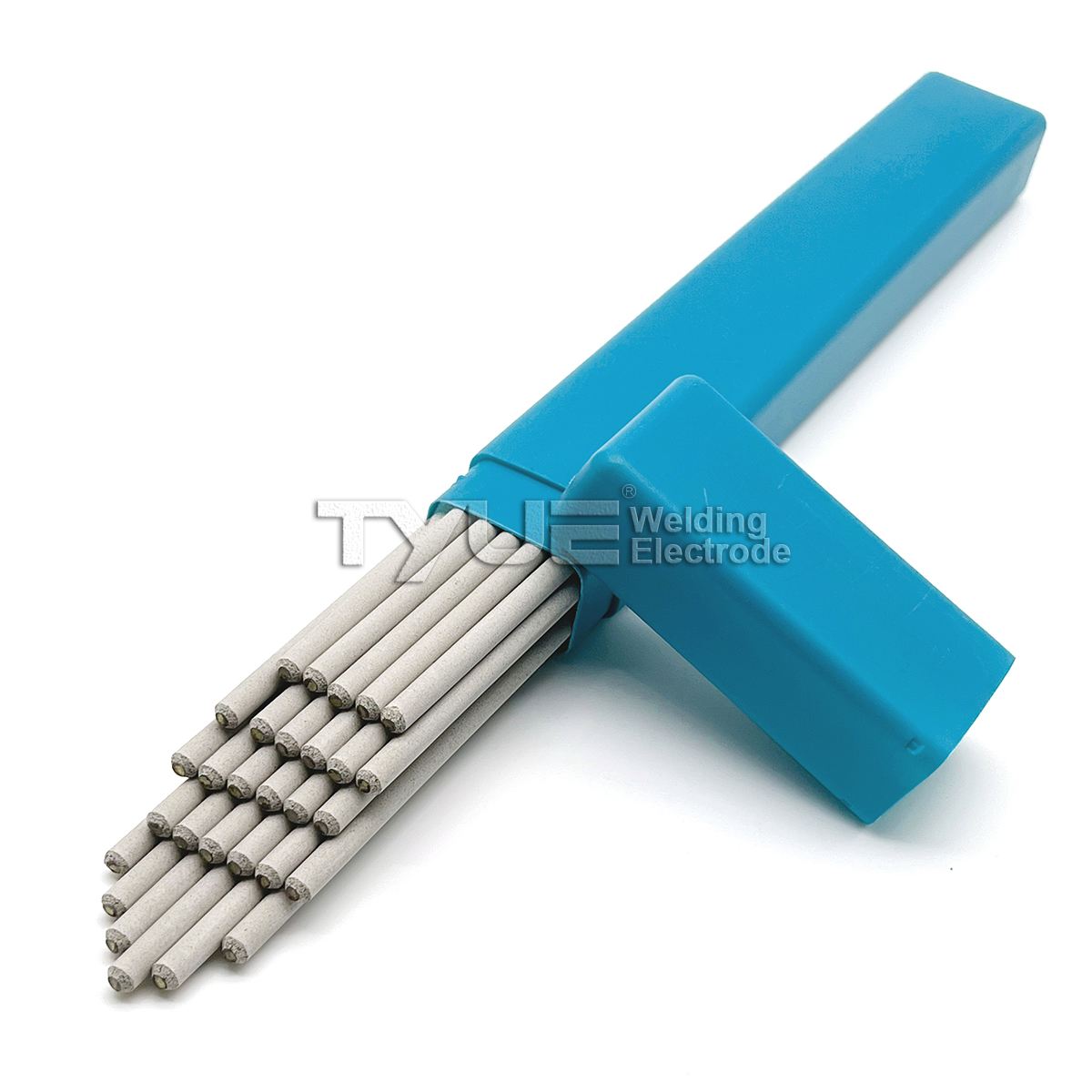

I-Electrode Yokushisela Yensimbi Ephansi Ye-Alloy

J557SLA、 J557SLB

I-GB/T E5515-G

I-AWS E8015-G

Incazelo: Lena i-electrode ekhethekile embozwe yi-hydrogen sodium ephansi yensimbi eyenziwe nge-aluminium. Sebenzisa i-DCEP (i-electrode yamanje eqondile), futhi ingashintshwa kuzo zonke izikhundla ngokusebenza okufushane kwe-arc. I-J557SLA ingashintshwa ngqo ngaphandle kokususa ungqimba olufakwe nge-aluminium ebusweni bomsele ngaphambi kokushintshwa. Kodwa i-J557SLB kufanele isuse ungqimba olufakwe nge-aluminium ebusweni bomsele ngaphambi kokushintshwa.

Ukusetshenziswa: Isetshenziselwa ukushisela isakhiwo sensimbi esenziwe nge-aluminium ngaphansi kwe-hydrogen sulfide, i-sulfur, i-ammonia, i-ammonium bicarbonate kanye ne-hydrogen nitrogen enezinga lokushisa elingaphansi kuka-540°C. Njengemibhobho yebhoyila, imishini yokucwenga i-petroleum, imishini yomanyolo kanye namapayipi omusi, njll.

Ukwakheka kwamakhemikhali kwensimbi eshidiwe (%):

| C | Mn | Si | Cr | Mo | Al | S | P |

| ≤0.12 | 0.50 ~ 0.90 | ≤0.50 | ≈0.80 | ≥0.20 | ≤0.055 | ≤0.035 | ≤0.035 |

Izakhiwo zemishini zensimbi yokushisela:

| Into yokuhlola | Amandla okudonsa I-Mpa | Amandla okukhiqiza I-Mpa | Ukwelulwa % | Inani lomthelela (J) Izinga lokushisa elijwayelekile. |

| Kuqinisekisiwe | ≥540 | ≥440 | ≥17 | ≥49 |

Okuqukethwe kwe-hydrogen okusakazwayo kwensimbi egciniwe: ≤6.0mL/100g (indlela ye-glycerin)

Ukuhlolwa kwe-X-ray: Ibanga lokuqala

I-current enconyiwe:

| (mm) Ububanzi benduku | 2.5 | 3.2 | 4.0 | 5.0 |

| (A) Ukushisela Kwamanje | 50 ~ 80 | 80 ~ 110 | 130 ~ 170 | 160 ~ 200 |

Isaziso:

1. I-electrode kumele ibhakwe ihora eli-1 cishe ku-350℃ ngaphambi kokusebenza kokushisela;

2. Kubalulekile ukuhlanza izikali zikawoyela, amanzi kanye nokungcola okugqwalile ezingxenyeni zokushisela ngaphambi kokushisela.