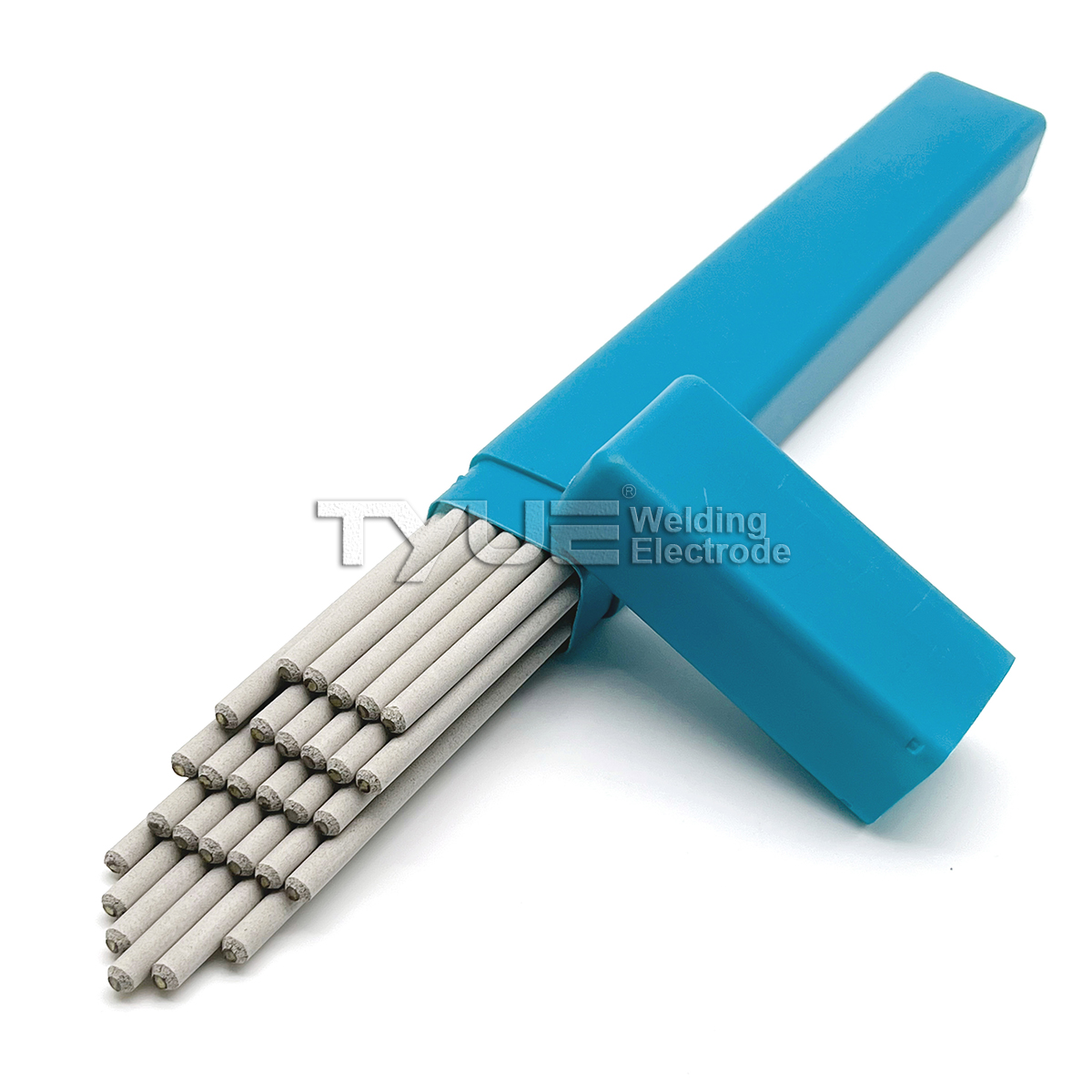

Ukushisela Insimbi EngagqwaliI-electrode

A207

I-GB/T E316-15

I-AWS E316-15

Incazelo: I-A207 iyi-electrode yensimbi engagqwali ye-Cr18Ni12Mo2 enekhabhoni ephansi ene-hydrogen sodium coating ephansi. Sebenzisa i-DCEP (i-electrode yamanje eqondile) futhi ingashintshwa kuzo zonke izikhundla. Njengoba insimbi efakiwe iqukethe i-molybdenum, inokumelana okukhulu kokugqwala, ukumelana nokushisa kanye nokumelana nokuqhekeka, ikakhulukazi okuhle ekumelaneni nokugqwala kwe-chloride ion pitting.

Ukusetshenziswa: Kusetshenziselwa ukushisela izakhiwo zensimbi engagqwali ze-06Cr17Ni12Mo2 ezinekhabhoni ephansi, kanye nezinsimbi ze-chromium ephezulu (njenge-Cr13, i-Cr17, njll.) ezingadingi ukwelashwa kokushisa ngemva kokushisela, kanye nokushisela izinsimbi ezingafani.

Ukwakheka kwamakhemikhali kwensimbi eshidiwe (%):

| C | Mn | Si | Cr | Ni | Mo | Cu | S | P |

| ≤0.08 | 0.5 ~ 2.5 | ≤0.90 | 17.0 ~ 20.0 | 11.0 ~ 14.0 | 2.0 ~ 3.0 | ≤0.75 | ≤0.030 | ≤0.040 |

Izakhiwo zemishini zensimbi yokushisela:

| Into yokuhlola | Amandla okudonsa I-Mpa | Ukwelulwa % |

| Kuqinisekisiwe | ≥520 | ≥30 |

I-current enconyiwe:

| Ububanzi benduku (mm) | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 |

| Ukushisela Kwamanje (A) | 25 ~ 50 | 50 ~ 80 | 80 ~ 110 | 110 ~ 160 | 160 ~ 200 |

Isaziso:

- I-electrode kumele ibhakwe ihora eli-1 cishe ku-250℃ ngaphambi kokusebenza kokushisela. Ungabhaki ngokuphindaphindiwe.

I-Wenzhou Tianyu Electronic Co., Ltd. yasungulwa ngo-2000. Besilokhu sihilelekile ekukhiqizenii-electrode yokushiselas, izinduku zokushisela, futhiizinto ezisetshenziswayo zokushiselaiminyaka engaphezu kwengu-20.

Imikhiqizo yethu eyinhloko ifaka insimbi engagqwalii-electrode yokushiselas, ama-electrode okushisela insimbi yekhabhoni, ama-electrode okushisela aphansi, ama-electrode okushisela okungaphezulu, ama-electrode okushisela i-nickel & cobalt alloy, izintambo zokushisela zensimbi emincane & i-low alloy, izintambo zokushisela zensimbi engagqwali, izintambo ezivikelwe ngegesi, izintambo zokushisela ze-aluminium, ukushisela kwe-arc okungaphansi komhlaba. izintambo, izintambo zokushisela ze-nickel & cobalt alloy, izintambo zokushisela zethusi, izintambo zokushisela ze-TIG & MIG, ama-electrode e-tungsten, ama-electrode okugoqa ikhabhoni, nezinye izesekeli zokushisela nezinto ezisetshenziswayo.